TOP 3 BENEFITS:

PRODUCT INFORMATION

The Sweepoff A & B are highly versatile: they are suitable for any speed application and for both low-level and high-level container outfeeds. They are adaptable to different layouts with in line / 90° outfeed configuration, and offer different magazine configurations according to raw materials to handle.

Different pallet sizes and heights can also be handled, with the Sweepoff A & B offering automatic changeovers for different product heights without mechanical intervention, all in less than 1 minute.

This line of depalletizers also boast improved ergonomics and safety, as well as optimized design and container holding:

The Sweepoff A & B are sustainable solutions, with high efficiency drives, low air consumption, only 2 cylinders and a low noise level.

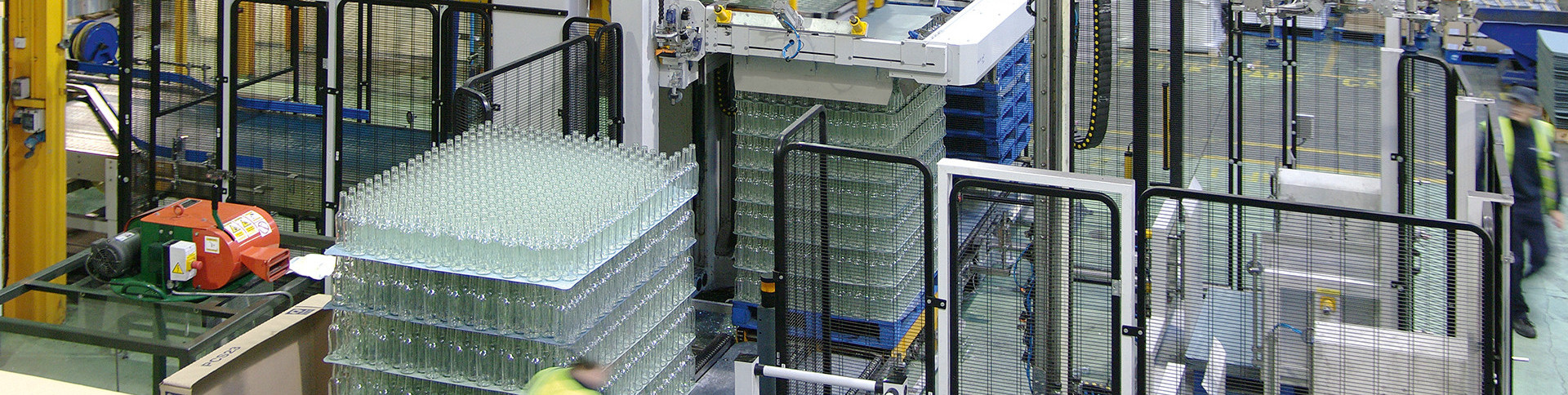

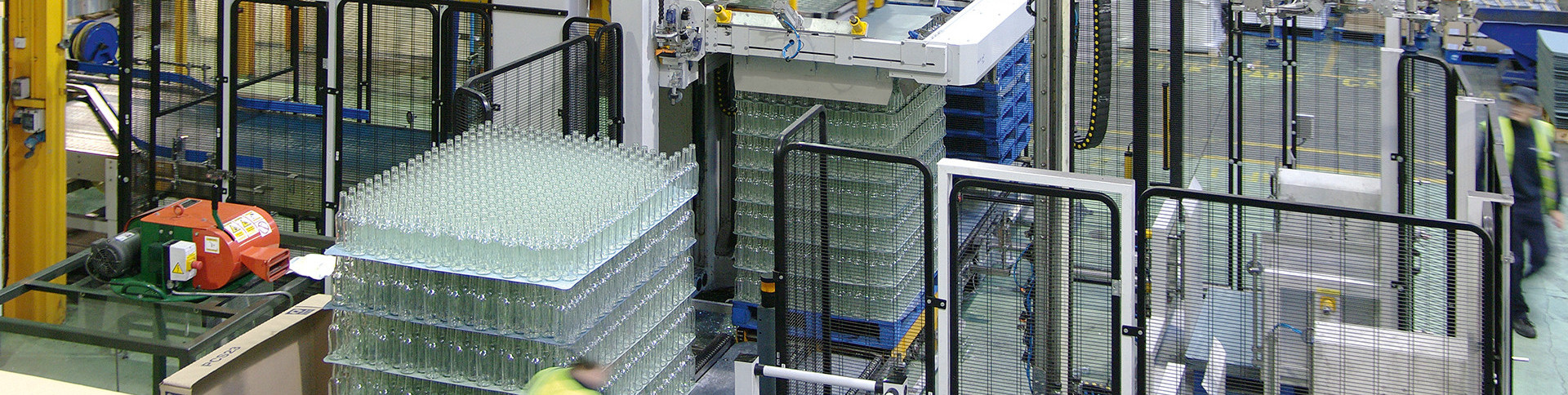

Automated high-level depalletizer

Sweepoff A is high-speed, reaching up to seven layers per minute. Well-suited to bottling lines with high outputs (up to 144,000 cph), this depalletizer is efficient due to its straight forward design, construction and operation.

Its benefits include:

Automated low-level depalletizer

Sweepoff B works at medium speeds, reaching up to three layers per minute. Particularly well-suited for glass bottling lines, this depalletizer can also handle PET bottles and offers easy access.

Its benefits include:

Always by your side on every step of the way to build, maintain and improve your line performance