With its magnetic flow meter, the Sidel Matrix™ Filler SF700 FM is able to fill PET bottles with still, pulpy beverages or those containing particles with the utmost precision and reducing beverage waste.

The Sidel Matrix filler SF700 offers the highest standards of hygiene and operational reliability during filling. This ensures it can meet the production demands of fresh, sensitive and natural beverages.

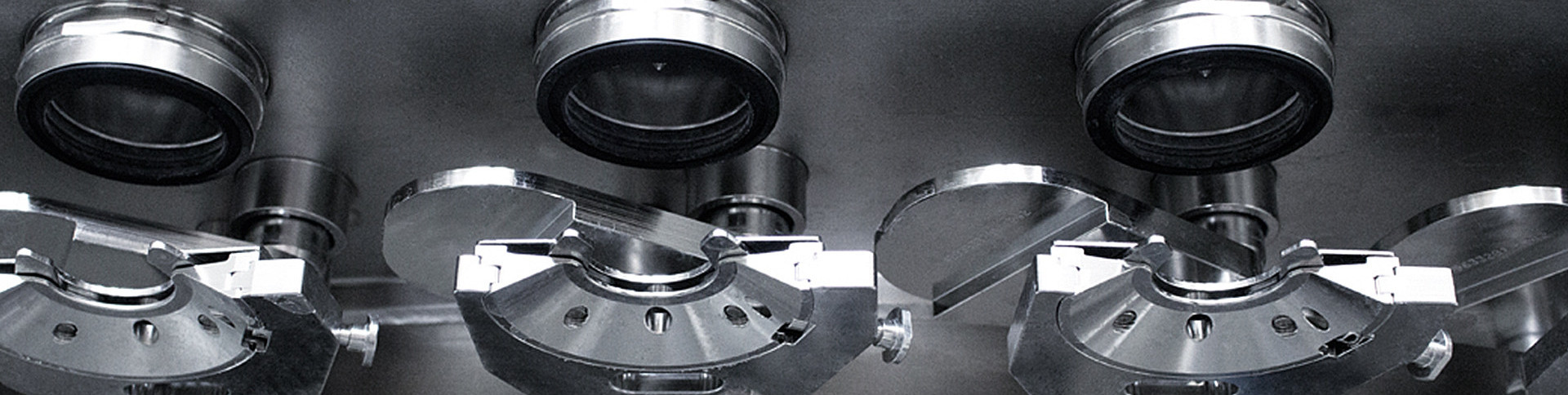

The Sidel Matrix hot filler features electronic filling valves equipped with individual flow meters that ensure precise filling volumes while minimising product wastage.

The flow rate from the tank to the filling valve can be easily controlled without any stress on the product, as any turbulence remains in the tank. Dual-speed filling eliminates foam generation while dual-stream dosing ensures that pulp or particles are delivered accurately and consistently.

The design of Sidel Matrix hot filler and its contactless filling valves optimises product safety throughout the packaging process.

| Bottles sizes | Max production output (bottles per hour) |

Range (number of valves) |

| 500 ml | 60,000 bph | 32 - 108 |

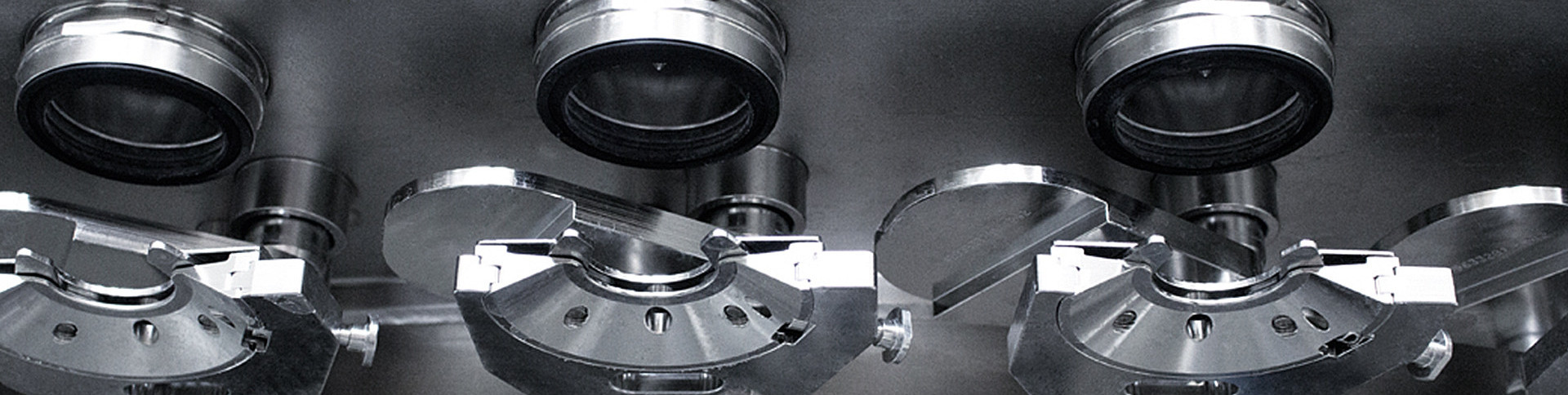

Dosing valve function:

Production of top quality beverages requires conditions of strict hygiene. Reuced filler enclosure improves food safety and reduces usage of chemical agents.

Always by your side on every step of the way to build, maintain and improve your line performance