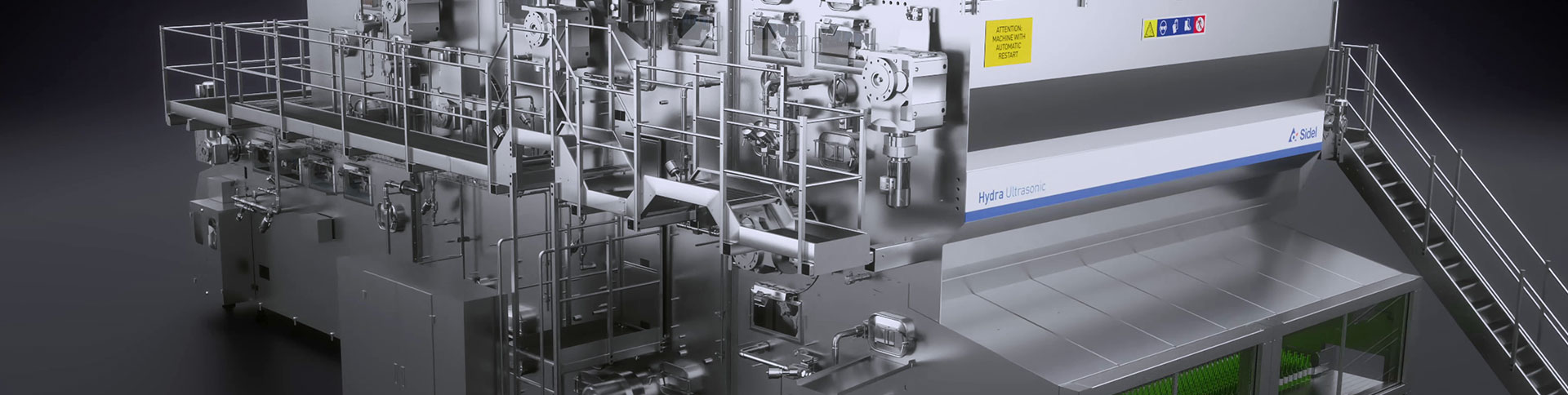

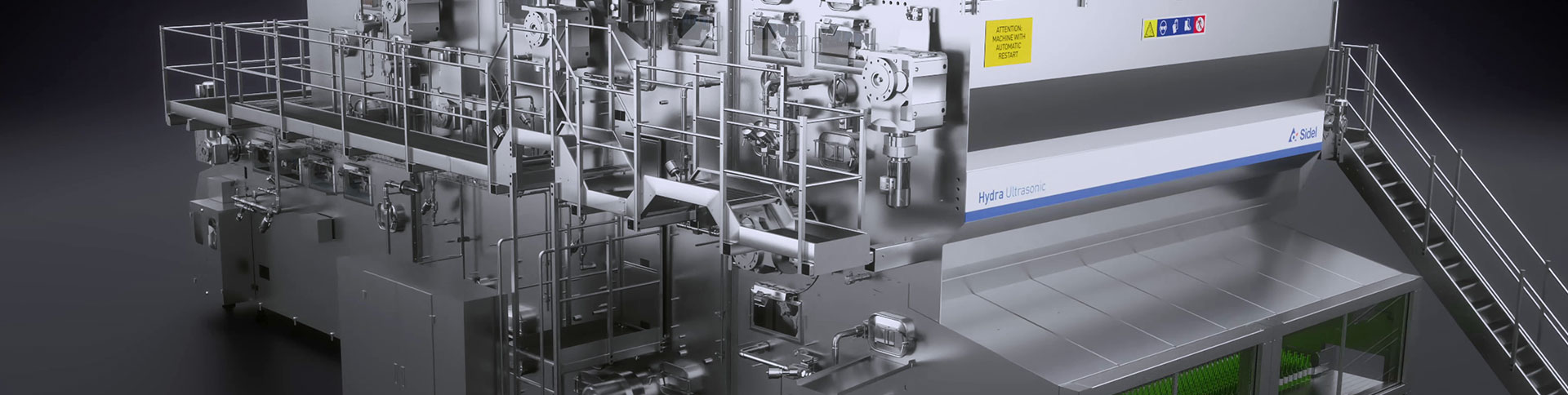

Real progress means doing more with less. Hydra Ultrasonic bottle washer has been designed to improve the machine's washing capacity, while at the same time reducing its carbon footprint and operating costs.

The use of ultrasounds, combined with chemicals, considerably increases the mechanical effect and the washing efficiency on both interior and exterior walls, removing caustic-resistant dirt, leading to lower rejection rates.

This dual technology not only reduces chemical consumption, but also significantly decreases the need for heat, steam, water and energy, thus ensuring much greater sustainability.

The new Hydra Ultrasonic finally supports beverage bottlers to reduce their total cost of ownership (TCO), requiring far fewer components and less maintenance, and reducing heating plant and overall footprint.

[1] Suitable for +10/15% production rate increase (with 75°C washing)

[2] Comparison with previous model. Calculation hypothesis: Formats: 330ml - 250g - 60.000bph, 660ml - 450 g - 40.000bph, fresh water temperature 20°C, bottle infeed temperature 25°C, bottle outfeed temperature 35°C

Always by your side on every step of the way to build, maintain and improve your line performance