The use of PET is steadily gaining market share in Food, Home Care and Personal Care (FHPC) markets traditionally dominated by HDPE (High Density Polyethylene) and PP (Polypropylene) and is expected to grow by an average of 3% for all three sectors until 2020.

Within these highly FHPC competitive markets, Sidel's new SteadyEDGETM base provides opportunities to accelerate the take-up of PET containers. It is designed to meet the challenge of producing flat, oval and rectangular containers in PET, which all require a specific production process that delivers the optimum material distribution of PET to achieve a top quality package.

The new base technology offers the possibility to create innovative and attractive PET package designs to differentiate brands while also ensuring bottle stability and cost-efficient production.

It is currently in use by customers in different parts of the world, with over 200 million containers already produced, and will shortly also be available for Sidel Matrix™ blowing machines.

Creative and distinctive package

With SteadyEDGE, brands will appear exactly as intended. It provides producers within the FHPC markets opportunities to differentiate their products and increase their market share with PET.

More stable package for optimum uptime

The sharper edges possible on the package are used to effectively flatten and increase the 'standing ring' area of the base, offering maximum production efficiency and performance.

A cost-efficient and sustainable production

This innovative packaging solution optimises productivity and low total cost of ownership (TCO) while product quality and reliability are maintained to a high standard.

Smarter blowing and quick changeover

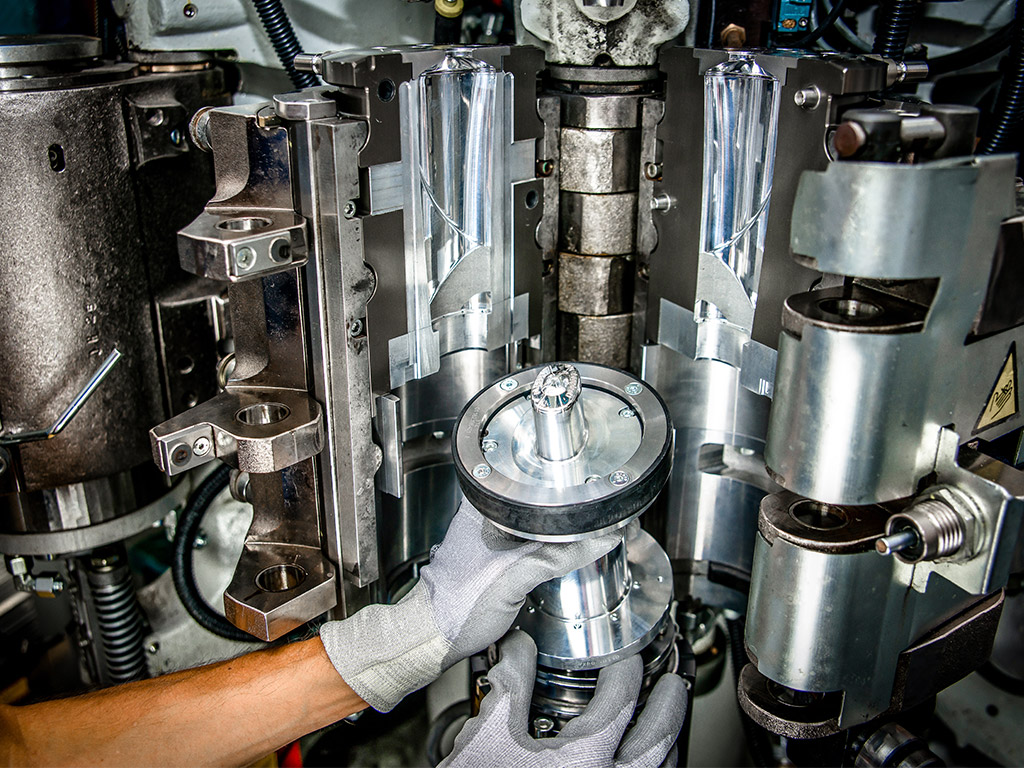

The specific sharp base design is achieved using the new Sidel patented base mould system: the Base OverStroke System (BOSS).