In today's ever-evolving market, consumers and regulations are demanding more than ever before. To stay ahead of the competition, you need to be prepared for the next challenge. At Sidel, we understand this need, which is why we have developed the most flexible and agile aseptic system available.

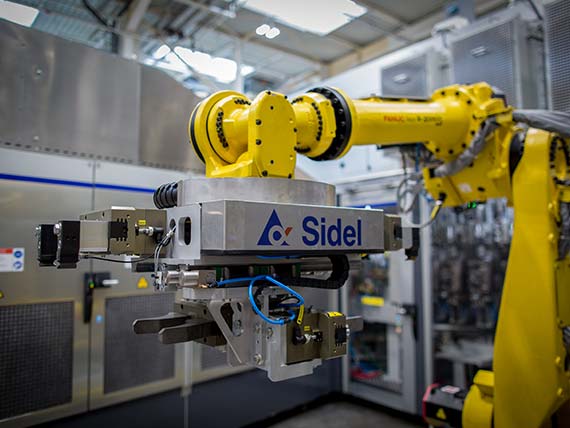

One of the key advantages of our system is its unmatched flexibility. You can make any necessary changes without compromising sterility. With a range of options, from easy manual adjustments to fully automatic solutions, you have the power to adapt and optimize your production process quickly and efficiently, ensuring your next batch is ready in record time.

As a proof of our commitment to flexibility, we developed a breakthrough ground floor preform feeder. This innovative feature allows for easy, fast and repeatable preform changeovers, minimising production interruptions and maximising efficiency. With our system, you can seamlessly transition between different preform types and sizes, safely and at ground level.

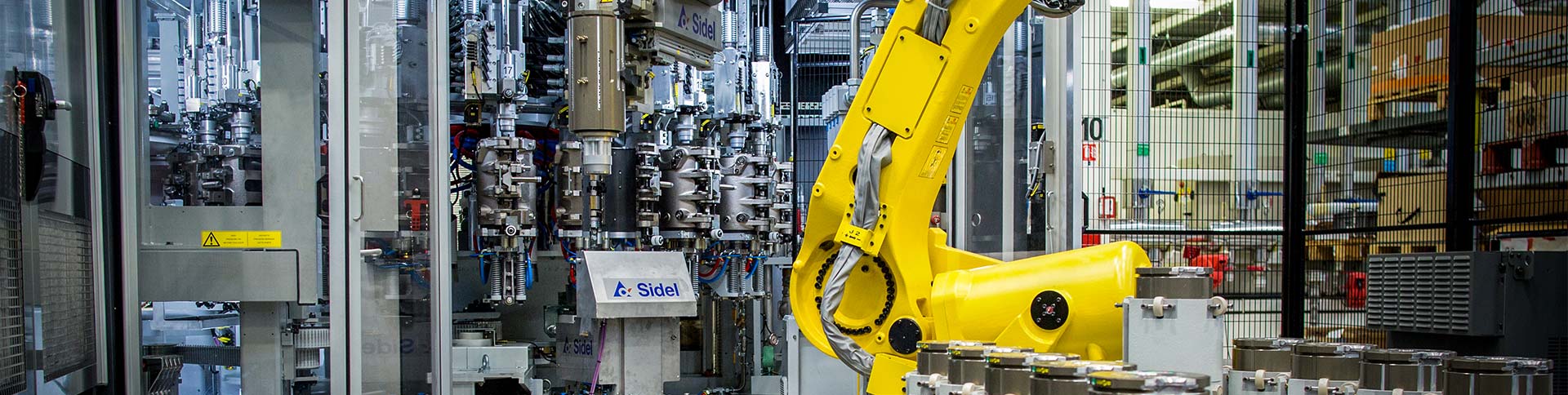

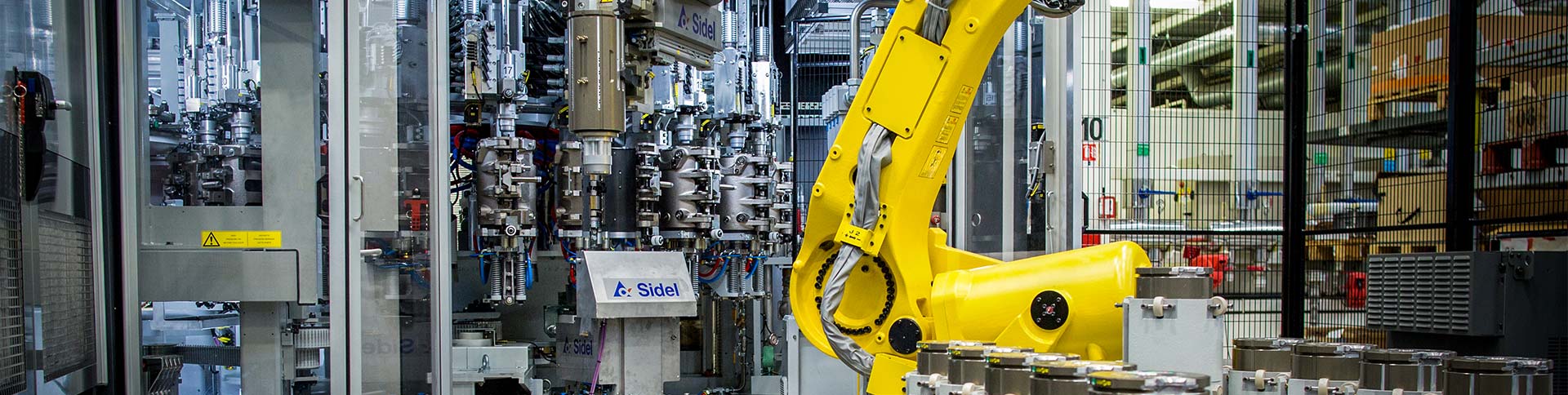

We have also developed a fully robotic solution for automatically change the blowing moulds. This eliminates the need for manual intervention, further streamlining your production process and reducing the risk of errors. Additionally, also our filler and capper operate seamlessly without requiring any manual intervention, ensuring a smooth and efficient operation from start to finish.