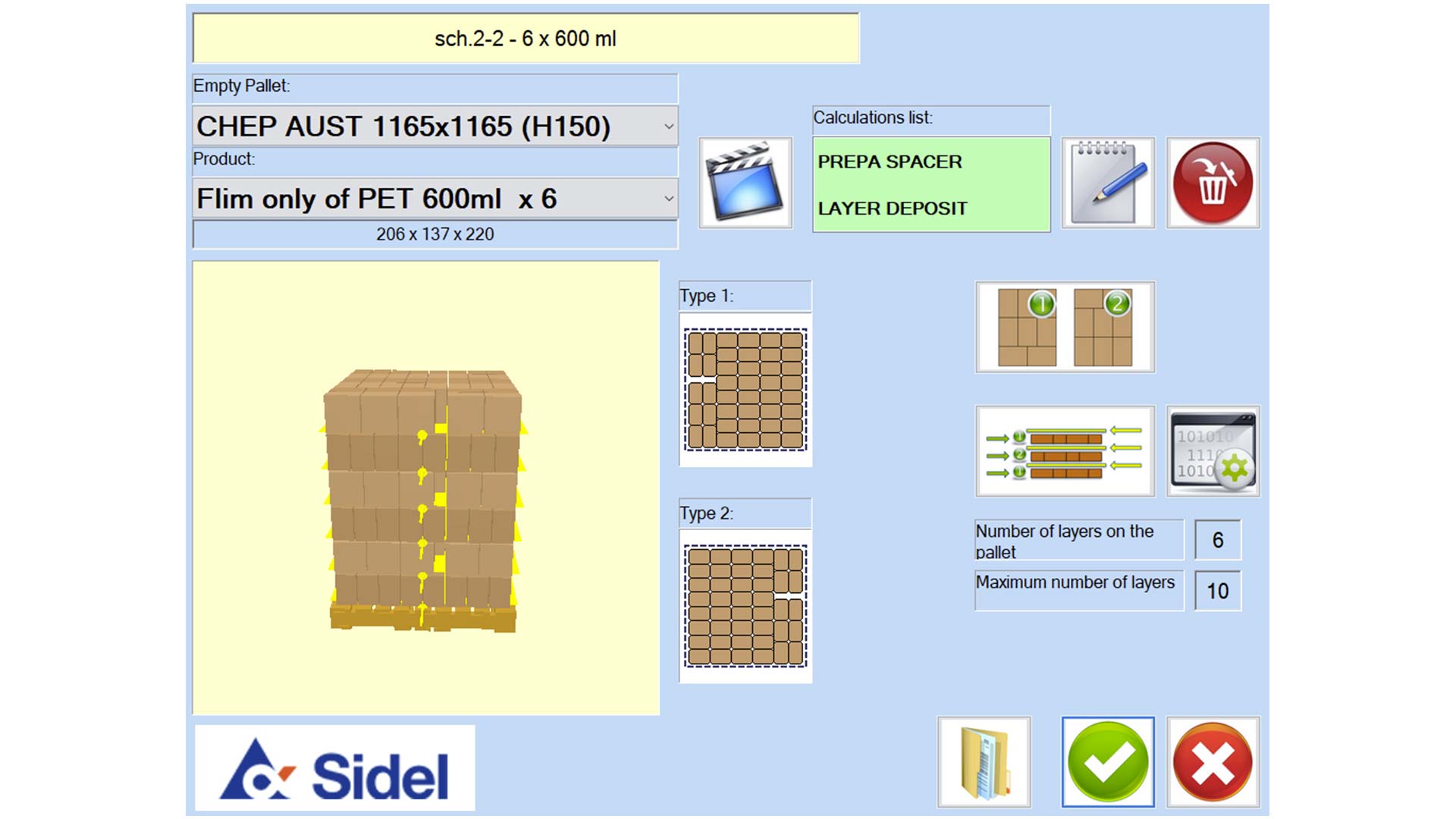

With today’s complex end-of-line operations, it’s impossible to overstate the importance of precise, flexible and reliable pallet configurations. Palletizing systems are often required to deal with a vast array of configurations. Exclusive PalDesigner® pallet programming software is a simple, intuitive interface which gives users absolute freedom to define the parameters of their products, batches, Stock Keeping Unit (SKU) and pallet sizes/patterns. PalDesigner® puts a host of state-of-the-art features at the fingertips of production and maintenance managers. They can then run through the whole process and, at the very end, use the 3D simulation function giving them further visual assurance about what they have created. PalDesigner® is particularly essential for companies performing palletizing operations that regularly include more than ten different pallet patterns, or more than three new configurations per year.

Meeting a wide variety of needs

We asked Fabien Chiron, Industrial IT Manager at the Saint-Laurent-sur-Sèvre plant, to explain a bit more about this technology: "After the great success of the original PalDesigner® software for layer-by-layer palletizers, the logical next step was to extend this solution to robotic palletizing operations. This new version is fully compatible with all new robotic palletizers. In addition, PalDesigner® is available as a retrofit upgrade for robotic cells already in operation. Ultimately it’s all about meeting the demands of our customers, who regularly have to deal with new products, new formats and new pallet patterns. PalDesigner® is a comprehensive palletizing software accessible directly via the palletizer’s HMI screen.”

A stunningly user-friendly process

- PalDesigner® comes pre-loaded with a huge range of pallet sizes and patterns, but also allows users to implement their own preferences in a seamless process:

- they simply enter the desired parameters (product dimensions, pallet layout and dimensions, etc.)

- the software will automatically take into account the environment (guarding/fencing, building layout) and integrate additional operation such as pallet and interlayer magazines.

- it will determine the movements and trajectories of the palletizing robot accordingly.

- it generates the optimal operating cycle using multi-case/pack picking and deposit, thereby assuring smoother operation with fewer accelerations and decelerations, and hence preserving the lifecycle of the equipment.

Process five times quicker

The end result is a pallet pattern creation process which is 5 times quicker than the existing methods, and also comes with a firm guarantee that the end result is efficient and workable, ensuring that no time-consuming adjustments will be needed once the palletizing operation has been launched.

PalDesigner® This easy-to-use software can be integrated directly into the palletizer’s touch-screen Human Machine Interface (HMI), as well as being installed on an external device for remote access, allowing users to prepare new formats “offline” and thus avoid making costly mistakes in the hectic production environment. There is even the option of linking PalDesigner® directly to an ERP or MES system for automatic changeovers and optimised production management.

Enhanced flexibility

The constant flow of new product formats, secondary packaging styles, pallet patterns and distribution requirements means that flexibility has never been more important when it comes to running a packaging end-of-line operation. Clients need to be able to quickly and efficiently create new patterns which are tailor-made to their precise requirements.

Nobody is more excited about PalDesigner®’s benefits for our clients than Giorgio Rocca, Sidel’s Palletization/Depalletization Product Line Manager: “Not only does the new PalDesigner® ensure maximum return on investment, it also offers an incredibly smooth and intuitive user experience. The new and improved PalDesigner® is already up and running on two packing lines, and we can’t wait to take it worldwide for all new Cermex robotic palletizers, and as a retrofit upgrade for robots already in operation.”