Miswa Chemicals UK is an internationally recognised manufacturer of automotive, household and insecticide products. Established in 1979, the family-owned company owns household brands Kilit, Pavan and Polyguard.

To move away from the manual loading of big metal cans, Jerry cans and aerosols in corrugated cases, Miswa Chemicals UK required a trusted partner for automatic case packing. Sidel delivered an affordable packing solution that could accommodate the different primary and secondary packaging shapes and types, while maintaining product integrity.

“The Sidel project team worked hard to understand our needs and offered a comprehensive tailored-made packing solution that aligned well with our various technical specifications from our different production lines,” explains Oren Patel-Champion, Director at Miswa Chemicals UK. “Sidel was one of the very few companies capable of addressing our diverse primary and secondary requirements with technically and economically adapted solutions from their existing proof-ready portfolio.”

Cardboard saving and cost-effective change part management with wrap-around packing

To replace the manual RSC (regular slotted container) packing for its aerosol metal spray with an automatic wrap-around packing variant, Sidel proposed the Cermex WB46 wrap-around case packer. This switch saves on annual corrugated cardboard volumes while allowing a reliable shelf ready possibility thanks to pre-cuts applied on the wrap around blank.

With its modular approach, the Cermex WB46 is competitive in many production configurations, from low speeds - such as the nine cases per minute at Miswa Chemicals’ plant - to high speeds of up to 28 cases per minute.

As products are transferred laterally in the wrap around case, this side-loading case packer is more economically adapted than Pick & Place solutions. When managing several product sizes and configurations, the cost of format parts, especially gripping toolings, is much higher as a set per format is required in contrast, side-loading only needs mechanical adjustments.

The Sidel case packer is also customised with a roof and reinforced safety glass guardings, to be compliant with the regulation related to explosion risks due to the presence of gas in the metallic aerosol cans.

Product integrity with bottom loading case packer

For the line producing large 3L and 4.5L metal cans of filler paste in RSC cases, Sidel’s packing experts advised to avoid a Pick & Place solution to overcome the risk of marking the cans with the grippers or opening the cans’ caps with a suction-based option.

The recommended solution, Sidel’s Cermex SF39 automatic case packer, loads the products by the bottom of the case maintaining product full integrity with a secured positive transfer by the base of the cans. The equipment can manage six to ten cases per minute according to the format and up to a maximum of 23 products per minute.

In addition, this affordable low-speed packer is also very cost-effective in case of multi format or SKU needs. Unlike Pick & Place solutions and like the Cermex WB46, the Cermex SF39 only requires mechanical adjustments for changeovers, with no additional format parts.

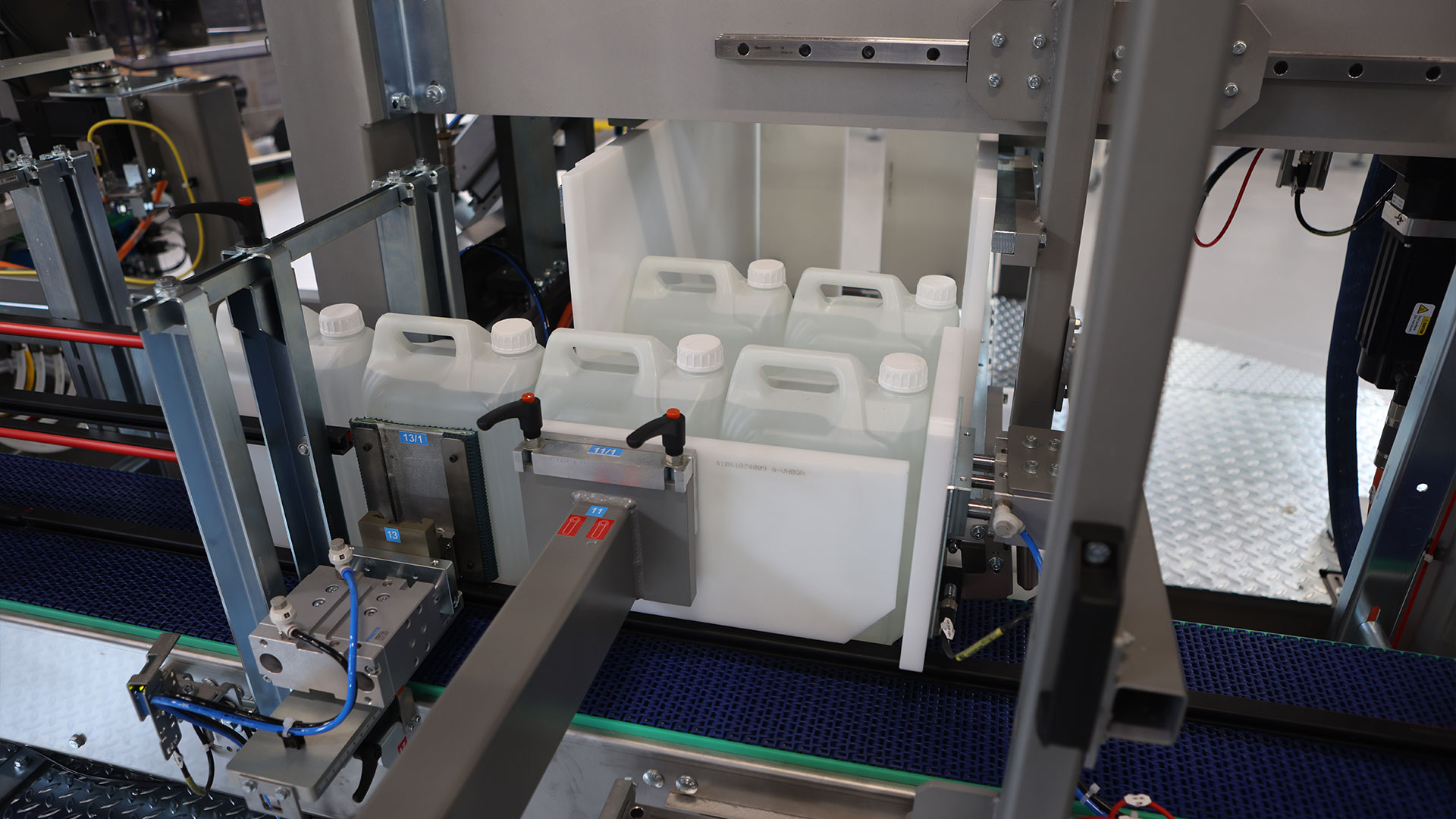

For the second line managing 5L Jerry cans, a similar affordable monobloc bottom loading Cermex SF39 case packer was selected to oversee 12 cases (24 products) per minute.

A good collaboration to achieve great results

Sidel’s collaboration with Miswa Chemicals is part of a wider complete line upgrade project that has led to an overall forty percent increase of the production capacity.

“The Sidel project team perfectly understood our needs and was reactive in providing us with good technical recommendations,” explains Oren Patel-Champion. “Even if Sidel is usually recognised for its high-end robotics and sophisticated technologies, they proved that their portfolio can also adapt to traditional low/medium speed applications for strong national players such as ourselves.”

The wide Sidel packing portfolio offers solutions for all case sizes, payload, and speed for any product types such as homecare, personal care, sauces and dressings, edible oil, biscuits, coffee, tea, and instant drinks.